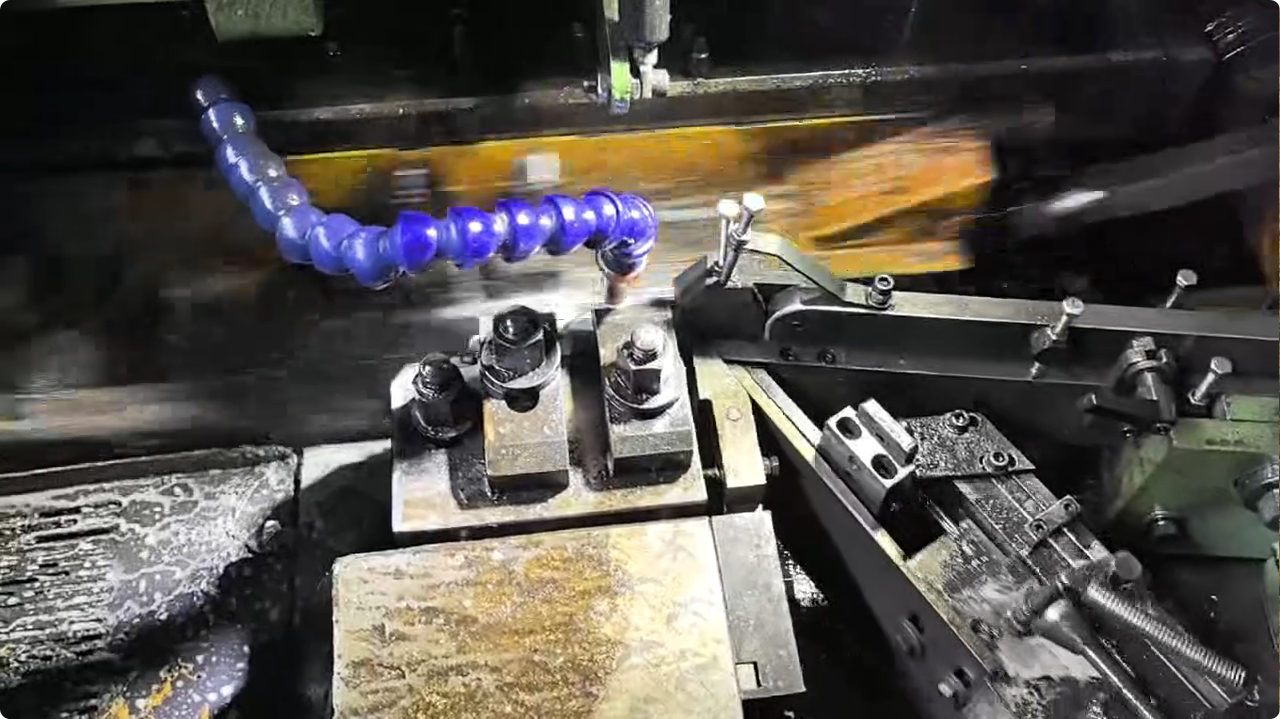

Двоштамповий прохідний верстат з двома штампамице пристрій холодного штампування, оснащений двома матрицями, в основному використовується для виробництва стандартних кріпильних виробів, таких як болти, штифти та заклепки. Він виконує дві послідовні операції - зазвичай для попереднього та остаточного формування - для забезпечення точної геометрії та поліпшення структурної цілісності. Принцип роботи полягає в тому, що дріт відрізається до фіксованої довжини, а потім за допомогою двох етапів обробки поступово формується бажана форма. Ця машина широко використовується у виробництві кріплень, де ефективність, стабільність і довговічність мають вирішальне значення.

| Модель | YTB-25152 |

| Діаметр заготовки (мм) | 8 |

| Максимальна довжина заготовки (мм) | 152 |

| Хід (мм) | 210 |

| Холостих обертів за хвилину | 60-70 |

| Діаметр матриці (мм) | 55 |

| Діаметр матриці Cof-off Dia (мм) | 28 |

| Пуансон (1-й) (мм) | 42 |

| Пуансон (2шт) (мм) | 42 |

| Двигун кузова | 7 1/2 К.С. |

| Двигун масляного насоса | 1/4HP |

| Габаритні розміри Д*Ш*В (мм) | 4000*1600*1650 |

| Вага Приблизно (кг) | 5500 |

Вибираючи обладнання для виготовлення кріплення, слід розуміти відмінності міжГоловні машини з двома штампамита інші технології заголовків мають важливе значення. Ось як машини з двома матрицями порівнюються з поширеними альтернативами:

Машини з двома штампами є підмножиною технології холодної висадки, оптимізованої для деталей середньої складності, пропонуючи хорошу пропускну здатність з точним керуванням. Інші машини холодної висадки з більшою кількістю штампів можуть обробляти складніші деталі, але з підвищеними витратами та складністю.