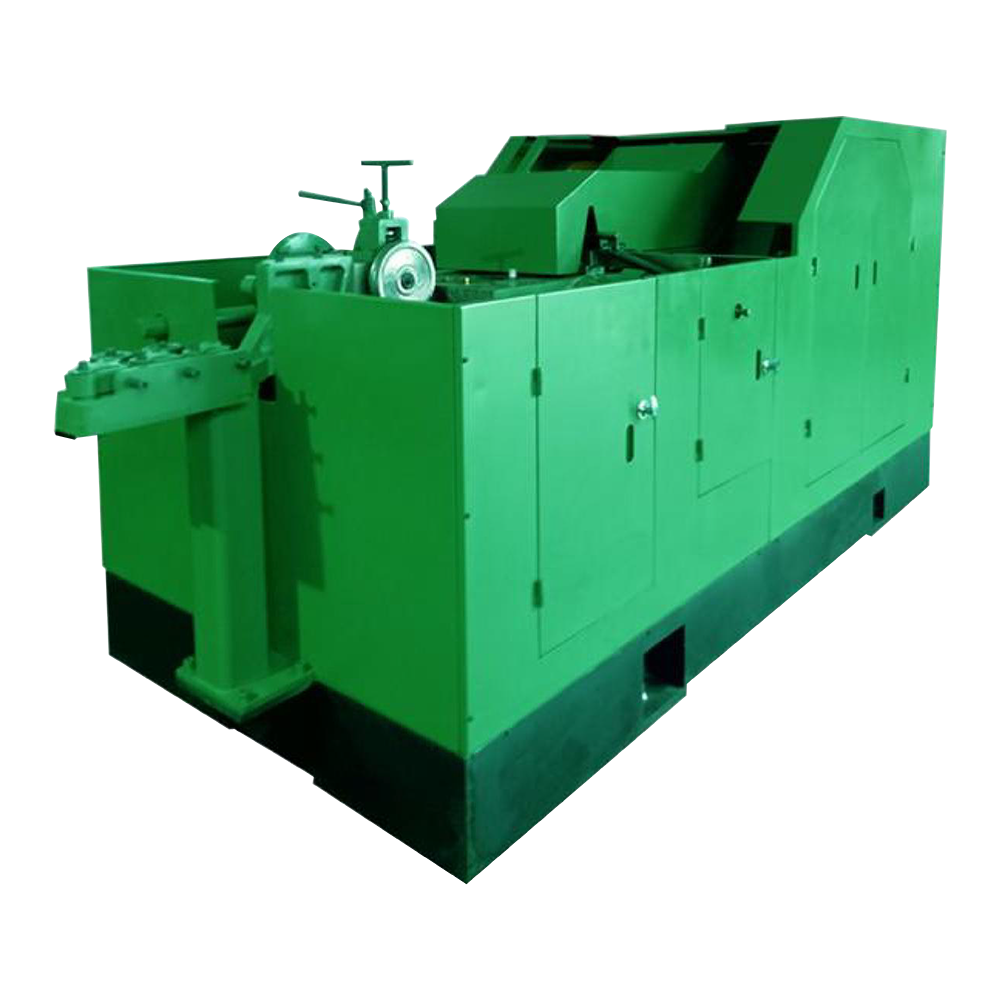

Це2-х станційний холодний колекторце машина холодної штамповки з двома робочими позиціями, яка використовується в основному для виробництва основних кріпильних виробів, таких як болти, заклепки та штифти. Він виконує два послідовних етапи формування для ефективного формування металевих заготовок, забезпечуючи рівномірні розміри та стабільну якість. Машина працює, розрізаючи дріт по довжині, а потім формуючи його за допомогою двох пуансонів у швидкій послідовності. Завдяки високошвидкісному циклу та надійній продуктивності, 2-станційний холодний штампувальний прес добре підходить для виробництва стандартних кріплень у загальній обробній промисловості.

| Модель | YT-25152 |

| Діаметр заготовки (мм) | 8 |

| Максимальна довжина заготовки (мм) | 152 |

| Хід (мм) | 210 |

| Холостих обертів за хвилину | 60-70 |

| Діаметр матриці (мм) | 55 |

| Діаметр матриці Cof-off Dia (мм) | 28 |

| Пуансон (1-й) (мм) | 42 |

| Пуансон (2шт) (мм) | 42 |

| Двигун кузова | 7 1/2 К.С. |

| Двигун масляного насоса | 1/4HP |

| Габаритні розміри Д*Ш*В (мм) | 4000*1600*1650 |

| Вага Приблизно (кг) | 5500 |

Машина повинна враховувати широкий вибір діаметрів і довжин болтів, що дозволяє виробникам випускати різні типи кріплень без частої зміни обладнання.

Шукайте машини, здатні виконувати високі ходи на хвилину, забезпечуючи ефективне масове виробництво зі збереженням стабільної якості.

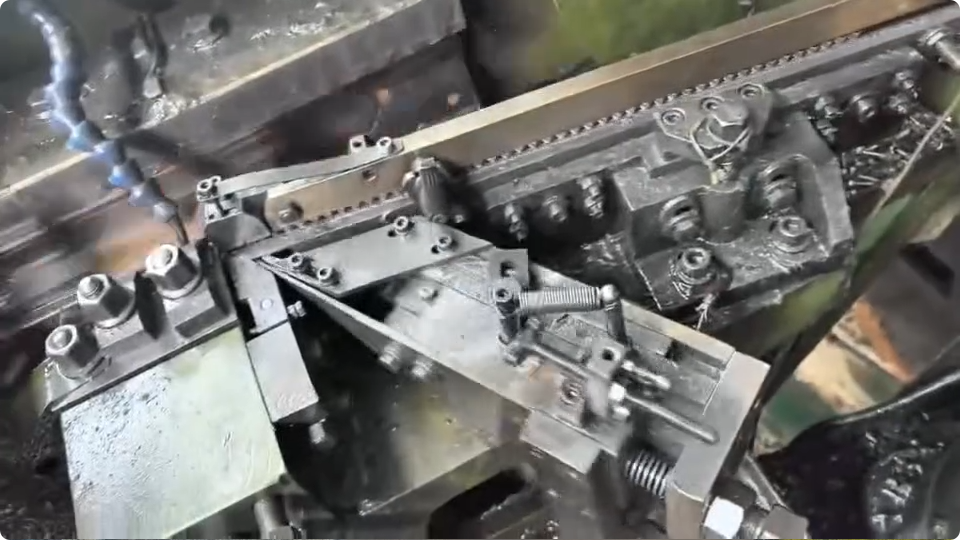

Швидка та проста заміна матриці допомагає мінімізувати час простою під час перемикання продукту, підвищуючи загальну гнучкість виробництва та скорочуючи час налаштування.

Переконайтеся, що холодна жатка може працювати з різними матеріалами, такими як вуглецева сталь, нержавіюча сталь, алюміній і латунь, щоб задовольнити різноманітні потреби застосування.

Автоматичні системи подачі, різання та викиду деталей дроту зменшують ручну працю, збільшують пропускну здатність і підтримують стабільний виробничий потік.

Системи з сервоприводом забезпечують нижчий рівень енергоспоживання порівняно з традиційними приводами, тоді як конструкції, орієнтовані на простоту обслуговування, допомагають скоротити час простою машини та експлуатаційні витрати.